PVC pem teb yog ntau heev nyob rau hauv niaj hnub chaw ua hauj lwm kho kom zoo nkauj, nrog rau qhov zoo ntawm waterproof, fireproof, mute, thiab lwm yam .Cov kauj ruam ntawm PVC pem teb thaum kho kom zoo nkauj yog raws li nram no:

1. Ncuav qhov sib xyaw nws tus kheej leveling slurry rau hauv pem teb kev tsim kho, nws yuav ntws thiab theem hauv av los ntawm nws tus kheej.Yog tias tus qauv tsim thickness tsawg dua los yog sib npaug li 4 hli, nws yuav tsum tau siv cov hniav tshwj xeeb los txhuam me ntsis.

2. Tom qab ntawd, cov neeg ua haujlwm tsim kho yuav tsum tau hnav cov khau tshwj xeeb thiab nkag mus rau hauv qhov chaw tsim kho.Tus kheej kheej kheej kheej kheej kheej kheej kheej kheej kheej kheej kheej kheej yuav tsum tau siv los yob maj mam rau ntawm tus kheej leveling nto kom tso cov huab cua sib xyaw ua ke, kom tsis txhob muaj npuas pockmarked nto thiab qhov siab sib txawv ntawm qhov sib txawv.

3. Thov kaw qhov chaw tam sim tom qab ua tiav kev tsim kho, txwv tsis pub taug kev hauv 5 teev, zam kev sib tsoo cov khoom hnyav hauv 10 teev, thiab nteg PVC pem teb tom qab 24 teev.

4. Hauv kev tsim kho lub caij ntuj no, hauv pem teb yuav tsum tau nteg 48-72 teev tom qab kev tsim kho tus kheej.

5. Yog hais tias nws yog tsim nyog los ua kom tiav polishing tus kheej leveling, nws yuav tsum tau nqa tawm tom qab tus kheej leveling cement yog qhuav kiag li.

Kev tshuaj xyuas ntawm kev tsim kho

1. Siv lub ntsuas kub thiab av noo los ntsuas qhov kub thiab av noo.Qhov kub hauv tsev thiab qhov kub ntawm qhov chaw yuav tsum yog 15 ℃, tsis yog kev tsim kho hauv qab 5 ℃ thiab siab dua 30 ℃.Cov huab cua txheeb ze tsim nyog rau kev tsim kho yuav tsum nyob nruab nrab ntawm 20% thiab 75%.

2. Cov ntsiab lus noo noo ntawm lub hauv paus chav kawm yuav tsum tau kuaj los ntawm cov ntsuas dej noo, thiab cov dej noo ntawm cov chav kawm hauv paus yuav tsum tsawg dua 3%.

3. Lub zog ntawm lub hauv paus chav kawm yuav tsum tsis txhob qis dua qhov yuav tsum tau muaj lub zog ua vaj tse C-20, txwv tsis pub nws tus kheej leveling yuav tsum tau saws los txhawb lub zog.

4. Cov txiaj ntsig kev xeem nrog hardness tester yuav tsum yog qhov nyuaj ntawm lub hauv paus yuav tsum tsis pub tsawg dua 1.2 MPa.

5. Rau kev tsim kho ntawm cov ntaub ntawv hauv pem teb, qhov tsis sib xws ntawm lub hauv paus chav kawm yuav tsum tsawg dua 2 hli nyob rau hauv 2m ncaj ntug, txwv tsis pub, kev ua kom zoo ntawm tus kheej yuav tsum tau saws rau qib.

Kev tu qhov chaw

1. Siv lub tshuab hauv pem teb uas muaj ntau tshaj 1000 watts thiab cov khoom sib tsoo uas tsim nyog los txhuam hauv pem teb tag nrho, tshem tawm cov xim, kua nplaum thiab lwm yam khoom seem, bulge thiab xoob av, thiab cov av khoob yuav tsum tau muab tshem tawm.

2. Hauv pem teb yuav tsum tau nqus thiab ntxuav nrog lub tshuab nqus tsev tsis muaj tsawg dua 2000 Watts.

3. Rau cov kab nrib pleb hauv pem teb, stainless hlau stiffeners thiab polyurethane waterproof nplaum yuav siv tau los pav quartz xuab zeb rau ntawm qhov chaw kho.

Kev tsim kho tus neeg saib xyuas interface

1. Lub hauv paus absorbent, xws li pob zeb, cement mortar thiab leveling txheej, yuav tsum tau muab kaw thiab primed nrog multi-purpose interface kho tus neeg saib xyuas thiab dej ntawm ib tug ratio ntawm 1: 1.

2. Rau cov chav kawm uas tsis yog absorbent, xws li cov pobzeb ceramic, terrazzo, marble, thiab lwm yam, nws raug nquahu kom siv cov khoom siv ntom ntom ntom ntom ntom rau hauv qab.

3. Yog hais tias cov dej noo ntawm lub hauv paus chav kawm siab dhau (> 3%) thiab kev tsim kho yuav tsum tau ua tam sim ntawd, tus neeg sawv cev kho mob epoxy tuaj yeem siv rau kev kho priming, muab cov ntsiab lus noo noo ntawm lub hauv paus chav kawm. tsis ntau tshaj 8%.

4. Tus neeg saib xyuas kev kho mob tau thov tusyees yam tsis muaj kev sib xyaw ua kua.Tom qab qhov saum npoo ntawm tus neeg saib xyuas kev kho mob yog cua qhuav, tom ntej no tus kheej theem kev tsim kho tuaj yeem nqa tawm.

Tus kheej leveling ratio

1. Ncuav ib pob ntawm nws tus kheej mus rau hauv lub thoob sib tov uas muaj cov dej ntshiab raws li cov dej cement piv, thiab ncuav thiab sib tov tib lub sijhawm.

2. Txhawm rau kom ntseeg tau tias txawm tias nws tus kheej leveling sib tov, nws yog ib qho tsim nyog yuav tsum siv lub tshuab hluav taws xob siab, qis-ceev hluav taws xob laum nrog lub tshuab tshwj xeeb rau kev sib tov.

3.S tir mus rau ib qho slurry yam tsis muaj caking, cia sawv ntsug thiab paub tab li 3 feeb, thiab do dua luv luv.

4. Tus nqi ntawm cov dej ntxiv yuav tsum nruj raws li cov dej cement piv (thov mus rau cov lus qhia txog tus kheej theem).Cov dej tsawg dhau yuav cuam tshuam rau qhov fluidity, ntau dhau yuav txo lub zog tom qab kho.

Kev tsim kho tus kheej leveling

1. Ncuav qhov sib xyaw nws tus kheej leveling slurry rau hauv pem teb kev tsim kho, nws yuav ntws thiab theem hauv av los ntawm nws tus kheej.Yog tias tus qauv tsim thickness tsawg dua los yog sib npaug li 4 hli, nws yuav tsum tau siv cov hniav tshwj xeeb los txhuam me ntsis.

2. Tom qab ntawd, cov neeg ua haujlwm tsim kho yuav tsum muab cov khau tshwj xeeb, nkag mus rau hauv av, siv qhov tshwj xeeb ntawm tus kheej leveling cua lub tog raj kheej kom yob maj mam rau ntawm tus kheej theem nto, tso cov huab cua sib xyaw ua ke, thiab tsis txhob muaj npuas pockmarked nto thiab interface. Qhov siab txawv.

3. Thov kaw qhov chaw tam sim tom qab kev tsim kho tiav, tsis txhob taug kev hauv 5 teev, tsis txhob cuam tshuam cov khoom hnyav hauv 10 teev, thiab nteg hauv pem teb tom qab 24 teev.

4. Hauv kev tsim kho lub caij ntuj no, hauv pem teb yuav tsum tau nteg 48 teev tom qab kev tsim kho tus kheej.

5. Yog tias nws yog qhov tsim nyog los ua kom tiav polishing tus kheej qib, nws yuav tsum tau nqa tawm 12 teev tom qab kev tsim kho tus kheej.

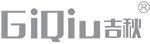

Ua ntej paving

1. Ob lub coil thiab thaiv cov ntaub ntawv yuav tsum tau muab tso rau hauv qhov chaw rau ntau tshaj 24 teev kom rov qab nco tau cov ntaub ntawv thiab ua kom qhov kub thiab txias raws li qhov chaw tsim kho.

2. Siv cov cuab yeej trimming tshwj xeeb los txiav thiab ntxuav cov ntug ntxhib ntawm lub kauj.

3. Thaum tso cov blocks, yuav tsum tsis muaj kev sib koom ua ke ntawm ob lub blocks.

4. Thaum tso cov ntaub ntawv coiled, qhov sib tshooj ntawm ob daim ntaub ntawv yuav tsum raug txiav los ntawm kev sib tshooj, uas feem ntau yuav tsum sib tshooj ntawm 3cm.Ua tib zoo khaws ib rab riam txiav.

Ci ntsa

1. Xaiv cov kua nplaum tsim nyog thiab roj hmab scraper rau hauv pem teb raws li kev sib raug zoo ntawm cov rooj txhawb nqa hauv phau ntawv qhia no.

2. Thaum cov khoom coiled yog pav, qhov kawg ntawm cov khoom coiled yuav tsum muab tais.Ua ntej ntxuav hauv pem teb thiab sab nraub qaum, thiab tom qab ntawd txhuam cov kua nplaum rau hauv pem teb.

3. Thaum paving block, thov tig lub thaiv los ntawm nruab nrab mus rau ob sab, thiab tseem ntxuav cov av thiab hauv pem teb thiab muab tshuaj txhuam nrog cov kua nplaum.

4. Cov nplaum sib txawv yuav muaj qhov sib txawv hauv kev tsim kho.Thov xa mus rau cov lus qhia khoom siv rau kev tsim kho.

Tso thiab Txhim Kho

1. Tom qab hauv pem teb yog pasted, thawj zaug thawb thiab nias lub hauv pem teb nto nrog ib tug mos ntoo thaiv kom qib thiab extrude cua.

2. Tom qab ntawd siv 50 lossis 75 kg steel roller yob hauv pem teb kom sib npaug thiab luas cov npoo ntawm qhov sib koom ua ke raws sijhawm.

3. Cov kua nplaum ntau dhau ntawm cov av hauv pem teb yuav tsum tau muab tshem tawm hauv lub sijhawm.

4. Tom qab 24 teev, ntswj thiab txuas dua.

Txoj kab

1. Slotting yuav tsum tau nqa tawm tom qab cov kua nplaum yog kiag li solidified.Siv ib qho tshwj xeeb slotter rau qhov sib koom ua ke.Txhawm rau ua kom lub vuam ruaj khov, lub slotting yuav tsum tsis txhob nkag mus rau hauv qab.Nws raug nquahu tias qhov tob qhov tob yog 2/3 ntawm cov hauv pem teb tuab.

2. Thaum kawg qhov twg seamer tsis tuaj yeem txiav, thov siv phau ntawv seamer txiav ntawm tib qhov tob thiab dav.

3. Ua ntej vuam, cov plua plav thiab cov khib nyiab seem hauv qhov zawj yuav tsum raug tshem tawm.

Vuam

1. Phau ntawv vuam phom lossis cov khoom siv vuam tsis siv neeg tuaj yeem siv rau vuam.

2. Qhov kub ntawm cov phom vuam yuav tsum tau teem rau ntawm 350 ℃.

3. Nias lub electrode rau hauv qhov qhib qhov zawj ntawm qhov kev sib txuas kom zoo (kom ntseeg tau tias cov electrode melting).

4. Thaum lub electrode yog ib nrab txias, siv lub electrode leveler los yog txhua hli cutter rau roughly txiav qhov chaw uas cov electrode siab tshaj lub dav hlau hauv pem teb.

5. Thaum lub electrode txias tag, siv lub tshuab electrode leveler los yog txhua hli cutter txiav cov seem convex ntawm electrode.

Post lub sij hawm: Jan-20-2021